Ga Alumina Refractory Castable

ọja Alaye

| Orukọ ọja | Refractory Castable |

| Awọn ẹka | Simẹnti Kekere / Castable Agbara giga /Castable Alumina Ga / Lightweight Castable |

| Tiwqn | Refractory aggregates, powders ati binders |

| Awọn ẹya ara ẹrọ | 1.Easy Ikole, 2.Good Slag Resistance, 3.Good Ipata Resistance, 4.Good Fire Resistance, 5.Energy Nfipamọ Ati Idaabobo Ayika. |

| Awọn ohun elo | Lilo pupọ ni Awọn ile-iṣẹ ile-iṣẹ iwọn otutu giga pupọ. |

| Awọn ọja | Low Cement Castable | Ga agbara Castable |

| Apejuwe | Awọn kasulu simenti kekere tọka si awọn kasulu tuntun pẹlu dipọ simenti kekere pupọ.Akoonu simenti ti awọn castables refractory jẹ gbogbo 15% si 20%, ati akoonu simenti ti awọn kasiti simenti kekere jẹ nipa 5%, ati pe diẹ ninu paapaa dinku si 1% si 2%. | Casable ti o ni agbara ti o lagbara ti o ni agbara ti o ga julọ, awọn admixtures nkan ti o wa ni erupe ile, apapọ agbara ti o ga ati egboogi kiraki ati aṣoju sooro. |

| Awọn ẹya ara ẹrọ | Idaduro mọnamọna igbona, resistance slag, ati resistance ogbara jẹ ilọsiwaju ni pataki, ti o kọja awọn biriki itusilẹ ti o jọra. | Agbara giga, resistance wiwọ ti o ga, ipadanu ipa, idena ogbara, ilodi epo-epo, iṣakoso apẹrẹ lainidii, iduroṣinṣin to lagbara, ikole ti o rọrun, iṣẹ ikole ti o dara, ati iṣẹ pipẹ. |

| Awọn ohun elo | 1.Lining ti awọn oriṣiriṣi awọn ileru itọju ooru, awọn ileru alapapo, awọn kilns ọpa, awọn kilns rotari, awọn ideri ileru ina, awọn tapholes ileru bugbamu; 2.Self-flowing low-cement castables ni o dara fun awọn ohun-ọṣọ ibon ti o ni iwọn otutu ti o ga julọ fun sokiri metallurgy ati petrochemical catalytic cracking reactors Wear-sooro ila, ode ti ita ti alapapo ileru omi-tutu paipu, ati be be lo. | Layer wiwu-sooro ti slag sluice,irin trough, edu spout, hopper ati silo ni metallurgy, edu, gbona agbara, kemikali,simenti ati awọn miiran ise, ati awọn bugbamu ileru dapọ silo, sintering silo, atokan, pelletizer, ati be be lo. |

| Awọn ọja | Alumina Castable giga | Lightweight Castable |

| Apejuwe | Awọn castables alumina ti o ga julọ jẹ ifasilẹcastables ṣe ti ga-alumina aise ohun elobi aggregates ati powders, o si fi kunpẹlu binders. | Casable iwuwo fẹẹrẹ pẹlu iwuwo olopobobo kekere jẹ ti simenti aluminate, ohun elo didara alumina giga, ceramsite, ati awọn afikun. |

| Awọn ẹya ara ẹrọ | Ni agbara ẹrọ giga ati resistance mọnamọna gbona gbona, resistance abrasion ati awọn ohun-ini miiran. | Iwuwo olopobobo kekere, adaṣe igbona kekere, ipa idabobo igbona ti o dara, agbara titẹ agbara giga, acid ati acid gaasi ipata resistance, idabobo ooru, idabobo gbona, ati gbigba omi kekere. |

| Awọn ohun elo | O ti wa ni o kun lo bi awọn akojọpọ inu ti igbomikana, bugbamu ileru gbona bugbamu adiro, alapapo ileru, seramiki kilns ati awọn miiran kilns. | Casable iwuwo fẹẹrẹ le ṣee lo fun Layer idabobo igbona ti ileru ile-iṣẹ iwọn otutu giga ati ohun elo tun ti a lo fun awọ ti ọpọlọpọ paipu gaasi iwọn otutu giga. |

Atọka ọja

Gbona aruwo adiro

Eefin Kiln

Rotari Kiln

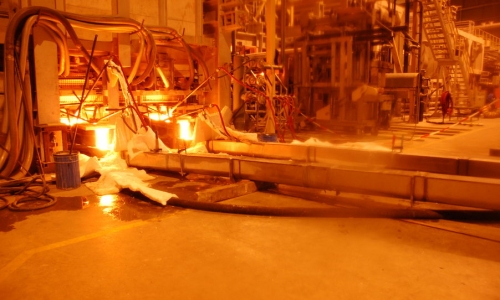

Irin ati ile-iṣẹ irin: lilo akọkọ fun itọju ati patching ti awọn ina arc ina, awọn ileru irin, awọn ladles ati awọn ohun elo miiran.

Ile-iṣẹ irin ti kii ṣe irin: ti a lo fun patching ati titunṣe ti bàbà, aluminiomu, zinc, nickel ati awọn miiran ti kii-ferrous irin gbigbo ileru ati awọn iyipada.

Ile-iṣẹ gilasi: ti a lo fun itọju ati iṣẹ patch ti awọn ileru gilasi, awọn ileru annealing ati awọn ohun elo miiran.

| Orukọ ọja | Low Cement Castable | |||||

| AKOSO | RBTZJ-42 | RBTZJ-60 | RBTZJ-65 | RBTZJS-65 | RBTZJ-70 | |

| Awọn iwọn otutu ti n ṣiṣẹ | 1300 | 1350 | 1400 | 1400 | 1450 | |

| Ìwọ̀n Ọ̀pọ̀ (g/cm3)110℃×24h ≥ | 2.15 | 2.3 | 2.4 | 2.4 | 2.45 | |

| Tutu atunse Agbara110℃×24h(MPa) ≥ | 4 | 5 | 6 | 6 | 7 | |

| Agbara Irẹjẹ tutu (MPa) ≥ | 110℃×24h | 25 | 30 | 35 | 35 | 40 |

| CT ℃×3h | 50 1300℃×3h | 55 1350℃×3h | 60 1400℃×3h | 40 1400℃×3h | 70 1400℃×3h | |

| Yẹ Linear Change@CT℃×3h(%) | -0.5 ~ +0.5 1300 ℃ | -0.5 ~ +0.5 1350℃ | 0~+0.8 1400 ℃ | 0~+0.8 1400 ℃ | 0 ~+1.0 1400 ℃ | |

| Resistance Shock Gbona (1000 ℃ omi) ≥ | ― | ― | ― | 20 | ― | |

| Al2O3(%) ≥ | 42 | 60 | 65 | 65 | 70 | |

| CaO(%) ≤ | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 | |

| Fe2O3(%) ≤ | 2.0 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Orukọ ọja | Ga agbara Castable | |||||

| AKOSO | HS-50 | HS-60 | HS-70 | HS-80 | HS-90 | |

| Iwọn otutu ti o ni opin iṣẹ (℃) | 1400 | 1500 | 1600 | 1700 | 1800 | |

| 110℃ Olopobobo iwuwo(g/cm3) ≥ | 2.15 | 2.30 | 2.40 | 2.50 | 2.90 | |

| Modulu ti Rupture (MPa) ≥ | 110℃×24h | 6 | 8 | 8 | 8.5 | 10 |

| 1100℃×3h | 8 | 8.5 | 8.5 | 9 | 9.5 | |

| 1400℃×3h | 8,5 1300 ℃ × 3h | 9 | 9.5 | 10 | 15 | |

| Agbara Irẹjẹ tutu (MPa) ≥ | 110℃×24h | 35 | 40 | 40 | 45 | 60 |

| 1100℃×3h | 40 | 50 | 45 | 50 | 70 | |

| 1400℃×3h | 45 1300 ℃× 3h | 55 | 50 | 55 | 100 | |

| Iyipada Laini Yẹpẹ(%) | 1100℃×3h | -0.2 | -0.2 | -0.25 | -0.15 | -0.1 |

| 1400℃×3h | -0,45 1300 ℃× 3h | -0.4 | -0.3 | -0.3 | -0.1 | |

| Al2O3(%) ≥ | 48 | 48 | 55 | 65 | 75 | 90 |

| CaO(%) ≤ | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 | 4.0 |

| Fe2O3(%) ≤ | 3.5 | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 |

| Orukọ ọja | Alumina Castable giga | ||||||

| AKOSO | Al2O3(%)≥ | CaO(%)≥ | Refractoriness (℃) | CT℃×3h PLC ≤1% | 110 ℃ Lẹhin Gbigbe (MPa) | ||

| CCS | MOR | ||||||

| Amo ti sopọ | NL-45 | 45 | ― | 1700 | 1350 | 8 | 1 |

| NL-60 | 60 | ― | Ọdun 1720 | 1400 | 9 | 1.5 | |

| NL-70 | 70 | ― | Ọdun 1760 | 1450 | 10 | 2 | |

| Simenti iwe adehun | GL-42 | 42 | ― | Ọdun 1640 | 1350 | 25 | 3.5 |

| GL-50 | 50 | ― | 1660 | 1400 | 30 | 4 | |

| GL-60 | 60 | ― | 1700 | 1400 | 30 | 4 | |

| GL-70 | 70 | ― | Ọdun 1720 | 1450 | 35 | 5 | |

| GL-85 | 85 | ― | Ọdun 1780 | 1500 | 35 | 5 | |

| Kekere Simenti iwe adehun | DL-60 | 60 | 2.5 | Ọdun 1740 | 1500 | 30 | 5 |

| DL-80 | 80 | 2.5 | Ọdun 1780 | 1500 | 40 | 6 | |

| Fọsifate ti so pọ | LL-45 | 45 | ― | 1700 | 1350 | 20 | 3.5 |

| LL-60 | 60 | ― | Ọdun 1740 | 1450 | 25 | 4 | |

| LL-75 | 75 | ― | Ọdun 1780 | 1500 | 30 | 5 | |

| Silicate iṣuu soda | BL-40 | 40 | ― | ― | 1000 | 20 | ― |

| Orukọ ọja | Lightweight Castable | ||||||

| Awọn iwọn otutu ti n ṣiṣẹ | 1100 | 1200 | 1400 | 1500 | 1600 | ||

| 110℃ Olopobobo iwuwo(g/cm3) ≥ | 1.15 | 1.25 | 1.35 | 1.40 | 1.50 | ||

| Modulu ti Rupture (MPa) ≥ | 110℃×24h | 2.5 | 3 | 3.3 | 3.5 | 3.0 | |

| 1100℃×3h | 2 | 2 | 2.5 | 3.5 | 3.0 | ||

| 1400℃×3h | ― | ― | 3 | 10.8 | 8.1 | ||

| Agbara Irẹjẹ tutu (MPa) ≥ | 110℃×24h | 8 | 8 | 11 | 12 | 10 | |

| 1100℃×3h | 4 | 4 | 5 | 11 | 10 | ||

| 1400℃×3h | ― | ― | 15 | 22 | 14 | ||

| Iyipada Laini Yẹpẹ(%) | 1100℃×3h | -0,65 1000 ℃× 3h | -0.8 | -0.25 | -0.15 | -0.1 | |

| 1400℃×3h | ― | ― | -0.8 | -0.55 | -0.45 | ||

| Imudara Ooru (W/mk) | 350 ℃ | 0.18 | 0.20 | 0.30 | 0.48 | 0.52 | |

| 700 ℃ | 0.25 | 0.25 | 0.45 | 0.61 | 0.64 | ||

| Al2O3(%) ≥ | 33 | 35 | 45 | 55 | 65 | ||

| Fe2O3(%) ≤ | 3.5 | 3.0 | 2.5 | 2.0 | 2.0 | ||

Ohun elo

Package&Ibi ipamọ